Machinery

Being involved in the composite industry, WTT is committed in providing Innovative Solutions to the Global Market. WTT offers systems, products and technology that set quality and production standards in a wide range of fluid handling applications including composite, glass reinforced concrete, and sealant and adhesives.

WTT is the AUTHORIZED DISTRIBUTOR of Graco GlasCraft machinery and equipment. We are the only company in the South East Asian region, who provides warranty, personalized training, machinery spare parts and the entire technical knowhow on the machinery and equipment. Staffed with qualified technicians trained in U.S.A, you can be assured that your purchases are guaranteed with quality training and genuine spare parts. Below are the machinery categories which are widely used for the composite markets.

Air-Driven Foam Proportioner – Economy Without Compromise

-

Designed for foam insulation applications, the Guardian A-5 is lightweight and easy-to-use.

Its LED controller lets you select temperature settings for three heat zones – ISO, resin and hose heat.

- Five-inch air motor delivers efficient and consistent operation

- Compact, portable, easy to move

- Independent digital controllers for ISO, poly, and hose heat

- Powerful heaters deliver 6,000 or 12,000 watts of primary heat to

reach set-point temperatures quickly and accurately

Air-Driven Proportioner for Coatings – Dependable Performance for Protective Coating

-

The plural-component fast-set coatings and linings market continues to expand in the global marketplace.

The Guardian A-6 reliably dispenses polyurea coatings and is designed for longer seal life and

less maintenance – which translates to more uptime and productivity for your business.

- Six-inch air motor delivers efficient and consistent operation

- Compact, portable, easy to move

- Independent digital controllers for ISO, poly, and hose heat

- Powerful heaters deliver 6,000 or 12,000 watts of primary heat to reach set-point

temperatures quickly and accurately

Low-Emission Resin Systems – Outstanding Performance For Resin Applications

-

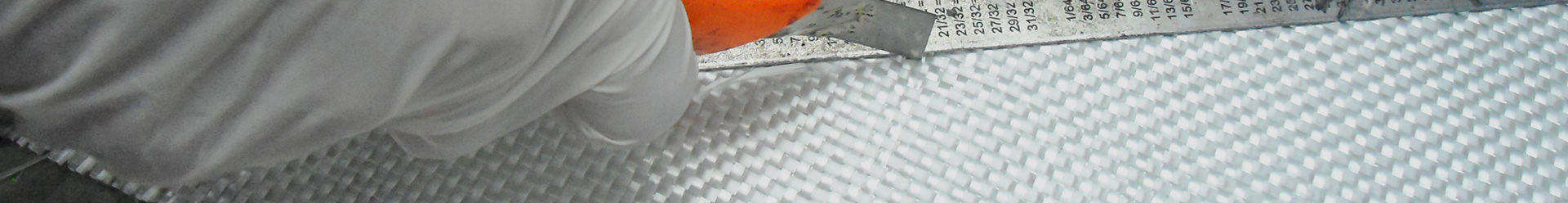

Designed to accurately meter and chop fibreglass into a resin spray to provide structural strength to the end product, GlasCraft Chopper/Wet-out.

Dispense Systems are engineered to deliver reliable performance.

Built with fewer wear items, GlasCraft equipment consumes fewer replacement parts.

With reduced service expenses and less revenue lost due to downtime, GlasCraft’s Chopper Systems are highly economical to own and operate.

FEATURES

- Dispense polyester resin and vinyl ester chemicals

- Allow for infinite adjustment of the catalyst ratio – no tools required

- Provide high-efficiency performance at low spraying pressure

- Available in internal and external mix configurations

Dispensing Equipment for RTM and Light RTM Applications – A Full Line Solutions for Resin Transfer Moulding

-

Resin transfer moulding (RTM) is a closed mould manufacturing process.

Finished parts are made by introducing polyester and vinyl ester resins into closed moulds containing fibreglass, carbon or other reinforcements.

FEATURES

- Engineered for low-pressure injection of polyester

and vinyl ester resins - Accu-Pressure sensor monitors and controls pressure

- Entry-level to automated, high-volume production models are available

Low-Emission Gelcoat Systems – Outstanding Performance for Gelcoat Applications

-

|  |

Designed for smooth, accurate gelcoat application, GlasCraft Gelcoat Dispense Systems are engineered to deliver reliable performance.

Built with fewer wear items, GlasCraft equipment consumes fewer replacement parts.

With reduced service expenses and less revenue lost due to downtime, GlasCraft’s Gelcoat Systems are highly economical to own and operate.

FEATURES

FEATURES

- Dispense pigmented, tooling, low-VOC and speciality gel coats

- Offer reliable, highly accurate catalyst percentage

- Provide high-efficiency performance at low spraying pressures

- Available in internal and external mix configurations

P.U. Dispensing System

-

The machine is portable, easy to operate and maintain.

It is suitable for pour and spray.

It is a low cost and useful machine.

Maintenance is very low, nearly zero.

The raw materials wasted is nearly to zero too.

The machine includes:

- 1 set of an air motor

- 1 set of material pump

- One complete set of the mixer head

- 1 set of gearbox

- 25FT hose set

- Portable case

The capacity is 7 Kg per minute. Compressor needs 5 H.P. or above.

GRC 3118 Spray System

-

Our very own WTT GRC3118 machine for the GRC industry. This machine is suitable to spray cement & glass fibre on the mould. It become a glass reinforce concrete, and can produce the followings:-

- Animal Statues

- Vall Plaques and corner frames accessories

- Light diffuseurs & corbel

- Ornamental pot of plant

- Splashing basins

- Cement rails

- Corinthians etc…

This machine includes:

- GRC Spray Gun

- One complete chopper

- 25FT. Matl. Hose Set

- 2 H.P/3 Phase 440 V.Elect. Motor with variable hydrostatic gearbox

- Material Mono Pump

- Electric/Pneumatic Box